What is recovered Carbon Black?

Recovered Carbon Black (rCB) is a processed solid residue created from the pyrolysis of end-of-life tires (ELTs). rCB can be made from many types of rubber waste, but ELTs are the most convenient because of their wide availability.

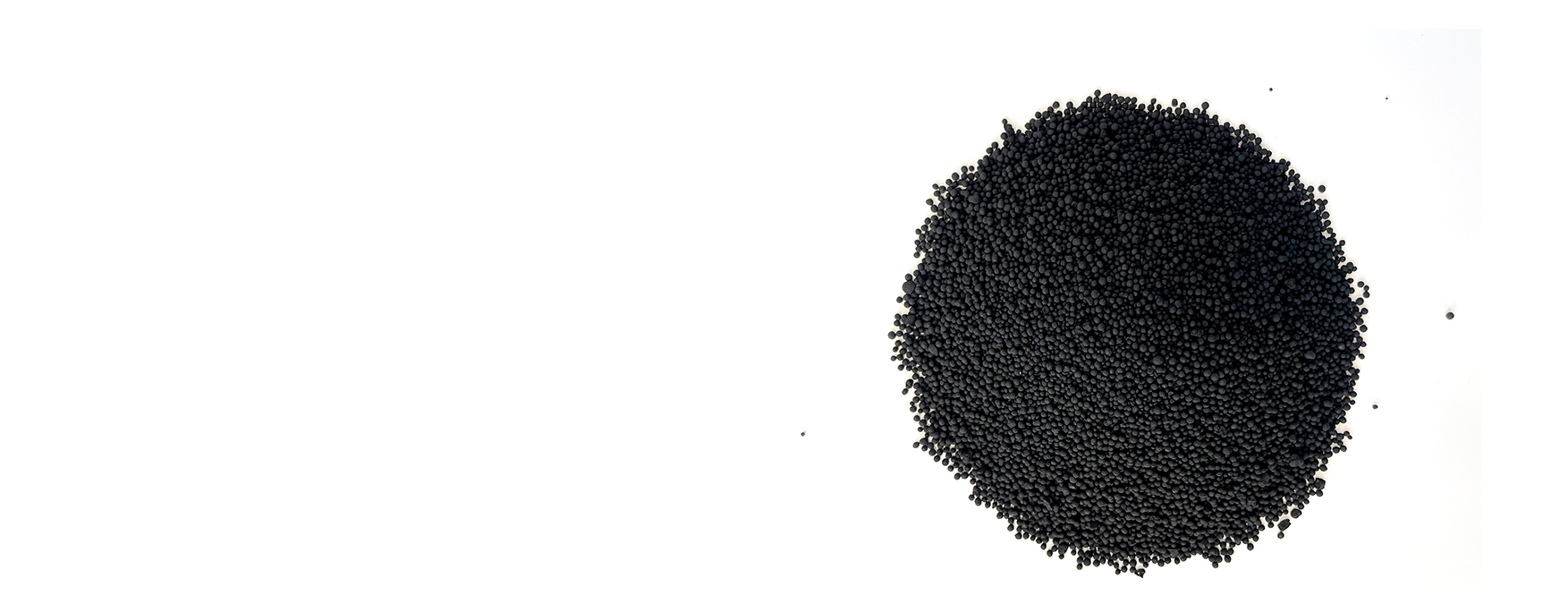

The pyrolysis process recovers various virgin Carbon Black (vCB) grades and mineral fillers present in the rubber. The raw product is called a char. The char is further processed, milled, and pelletised to become recovered Carbon Black. rCB contains around 20 per cent less carbonaceous material in comparison to virgin Carbon Black, because of the presence of minerals. However, rCB is still a high-quality product with many applicable uses.

The in-rubber performance of rCB produced by Contec is very similar to several grades of virgin Carbon Blacks that are widely used in the tire manufacturing industry. The rCB carbon footprint is over 80 per cent lower in comparison with vCB.

Meaning, that there is a large push in the tire manufacturing industry to pivot towards rCB in production.