Treść główna

Recovered Tire Pyrolysis Oil – ConPyro®

What is tire pyrolysis oil?

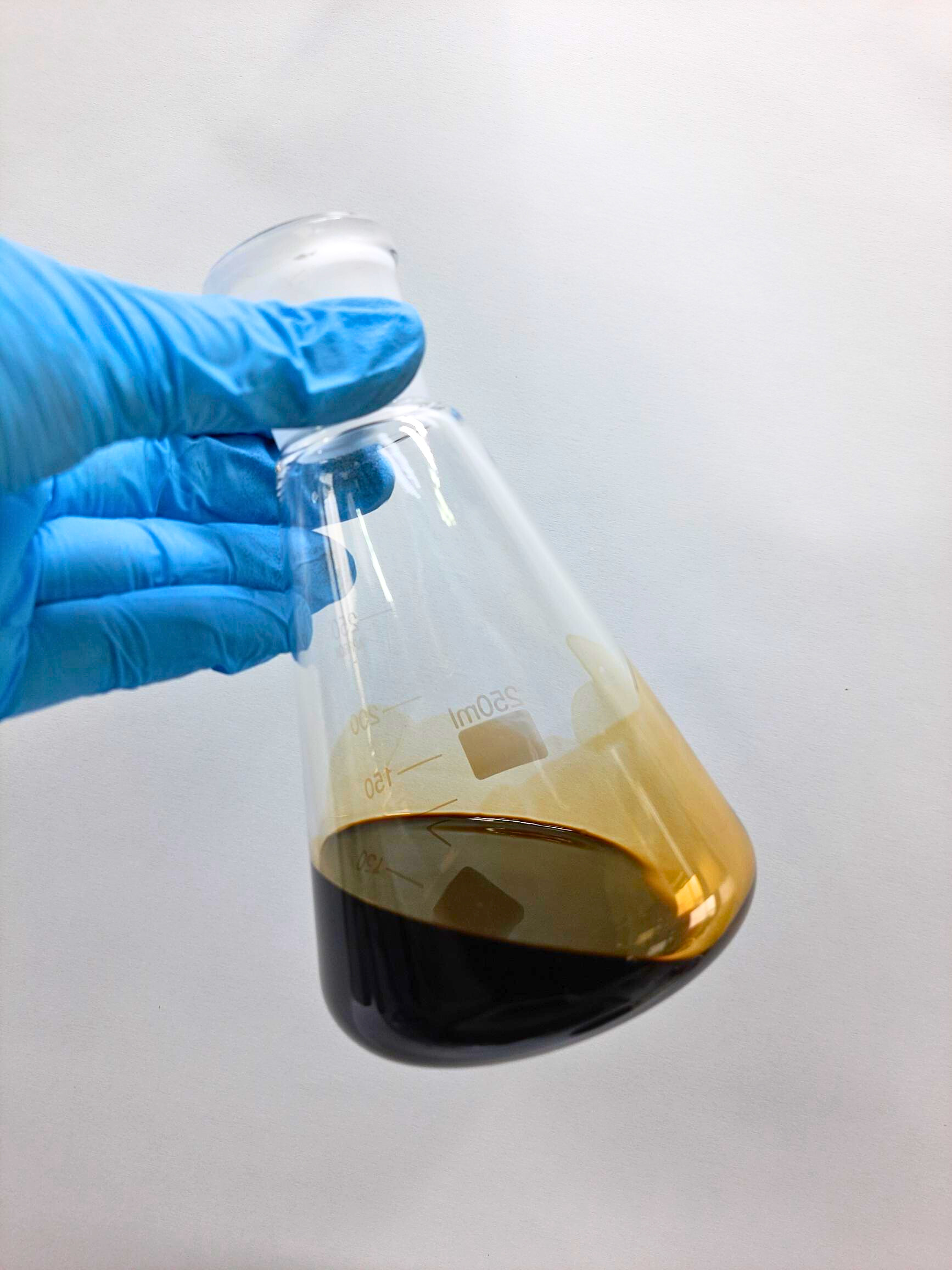

Tire pyrolysis oil (TPO) is the liquid fraction produced through the pyrolysis of end-of-life tires (ELTs). It’s a thick, viscous dark brown or black liquid, that is unique and not a typical crude oil.

It has a high amount of aromatic hydrocarbon content, over 50 per cent. This significant amount of carbon is bio-based because end-of-life tires (ELTs) are partly made of natural rubber.

After several finishing processes, it can be used as a circular feedstock in the chemical and oil & gas industry.

Applications for recovered tire pyrolysis oil

Recovered tire pyrolysis oil (TPO) can be a circular opportunity for many fossil-based feedstocks and oils.

The main applications for tire pyrolysis oil have been explored as a fuel for engines, heating and power generation, and feedstock for producing Carbon Black and other chemicals. But it can also be further evaluated as circular options in these areas:

Refineries

Plastics

Fuel additives

How Contec manufactures tire pyrolysis oil

During the pyrolysis process, the rubber granulate is heated to temperatures of up to 550oC in our specially designed two-stage auger reactors.

More than 60 per cent of rubber mass vaporises into gaseous products. As the reactors cool, around 80 to 90 per cent of that mass is condensed into a crude recovered tire pyrolysis oil.

The result is Contec’s ConPyro®, a recovered tire pyrolysis oil, that has a low carbon footprint of only 399.75 kg CO2e/1t.

Why choose ConPyro®

01. High-quality recovered tire pyrolysis oil

At Contec, we ensure that our circular feedstock is of the highest standard and produced under optimal conditions.

We check quality at every stage of the manufacturing process – from the initial tire shredding and pyrolysis process to the testing of the end product in our in-house laboratory. The recovered tire pyrolysis oil undergoes stringent quality control and testing, where we perform regular checks and adhere to a consistent schedule.

Regular preventative maintenance and quality measures are where our on-site team of technicians and engineers take immediate steps to identify and rectify the cause of any pyrolysis improvements.

02. Innovative technology development

We invested heavily in the research and development of the entire pyrolysis process.

Our team closely facilitated the beginning of R&D with the Warsaw University of Technology and continued during the technology design, the building of the pilot plant, and the launching of the technology demonstrator. We now have two pyrolysis lines in operation at the Szczecin plant.

R&D at Contec continues because it’s essential to finding viable circular solutions that enable manufacturers to reach Net Zero targets. The unique R&D process improves the laboratory facilities and tests the effect of every technology process change on product quality.

03. Safe process

Many industrial manufacturing processes present considerable safety hazards and risks.

We take great care to make the pyrolysis process as safe as it can be for our workers by implementing safety protocols and applying controlled spaces in the plant.

All of the processes at our full-scale production location comply with safety and quality standards which are reviewed by external auditors. We regularly perform operator training and have safety procedures in place. We also apply automated safety systems to the technology. As experienced operators, we know that safety comes with preventative maintenance.

04. Sustainability-focussed

Sustainability is woven into our company’s DNA. We aim to recycle 100 per cent of the ELTs that come into our plant to help reduce carbon emissions and cut material waste.

We’re improving the efficiency and sustainability of our plant and operations to limit the company’s carbon footprint.