Treść główna

Guaranteed quality products

Contec provides high-quality end products upcycled from end-of-life tires. We ensure the best quality and most sustainable products available on the market.

View productsFirst-class products, a novel technology

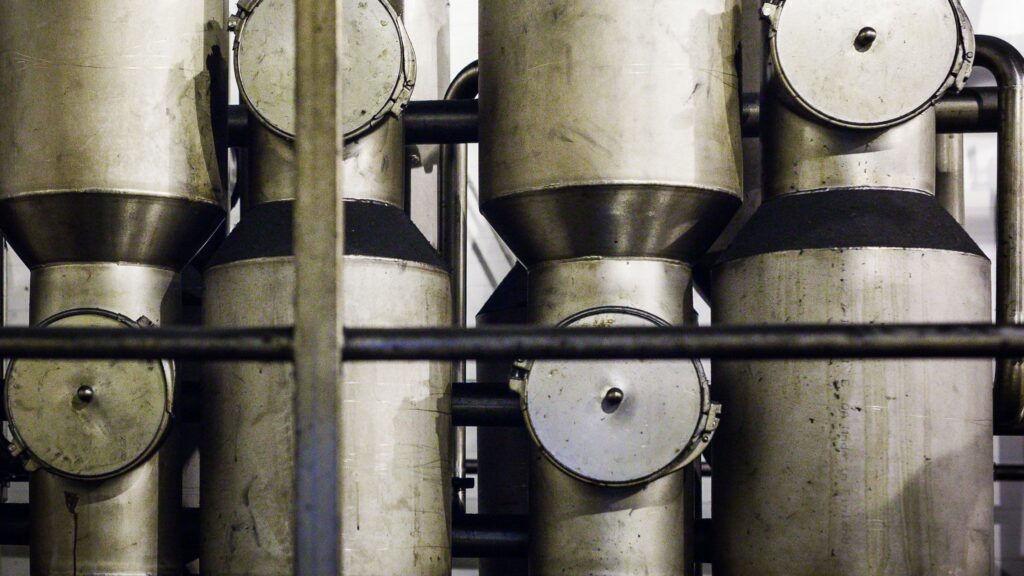

Contec’s high-quality products are derived from our state-of-the-art pyrolysis technology.

We’re the only company in the world that uses molten salts as a heat transfer medium in the pyrolysis process.

Using a continuous process involving molten salt provides the conditions for a safer, more efficient, and highly economical production method, designed with repeatable quality in mind.

For over five years, we’ve perfected and optimised this technology to produce a cleaner alternative to virgin Carbon Black and petrochemical feedstocks, while also addressing the global waste problem of end-of-life tires.

We collaborated with experts in the field to develop the pioneering pyrolysis process. Our team of in-house engineers and external partners created the technology in unison with technological institutions like the Warsaw University of Technology. Special attention was given to a process that is suitable for a variety of applications and can be further adapted for other feedstocks.

Currently, we’ve successfully built, optimised, and now operate two pyrolysis lines in our large-scale pilot plant in Szczecin, Poland.

Learn more

Sustainability at our core

We believe that circular economy manufacturing in the tire industry is possible, and we’re actively supporting the industry to evolve towards a “tire-to-tire” model.

Read our vision

Is pyrolysis better than gasification?

The countdown to the completion of our plant expansion work in Szczecin is well underway!